A masterpiece significantly improved

*Please note that there are different country versions of this press release available BG | CZ | DE | DK | EE | EN | ES | FI | FR | HU | IT | LT | LV | NL | PL | RO | RU | SE

Find them in the media set to download.

Festool has a new highlight for tradespeople of all trades. The German brand manufacturer has continued to make decisive improvements to its new plunge-cut saws: They will be able to saw twice as fast, and the TSC 55 K cordless plunge-cut saw will be available immediately with the unique KickbackStop.

In one's working life, often even just a millisecond is crucial: Kickback is the most common cause of serious injuries when using a plunge-cut saw. Particularly when plunging the saw blade into the workpiece, conventional plunge-cut saws may kick back when the saw blade tilts. This is why Festool focused on preventing dangerous kickbacks during further development.

Unique KickbackStop

The new cordless TSC 55 K plunge-cut saw is equipped with the newly developed, unique KickbackStop. This technology ensures that the saw blade on the plunge-cut saw responds to kickbacks and stops faster than the blink of an eye. The backwards movement is also stopped at the same time, thus preventing both injuries and damage to the workpiece.

Exceptional battery performance

With the new TSC 55 K, you will be able to work up to twice as fast in the future whilst also benefiting from a longer battery life. In other words: Maximum cutting power meets perfect cut quality. With this new development, Festool is dispelling the preconception that cordless saws cannot deliver the same performance as corded tools. The combination of the latest generation of brushless EC-TEC motor technology and dual battery system (2x18 V) makes the new TSC as powerful as a mains-operated plunge-cut saw and provides mobility at the same time. The latest saw blade generation also ensures both fast work progress and precise cutting quality.

Corded power

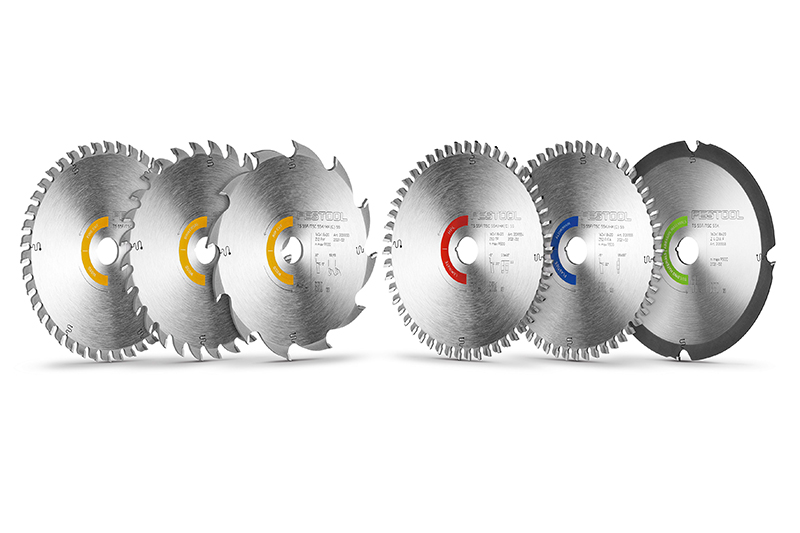

The corded variant of the new plunge-cut saw – the TS 55 F – now also saws up to twice as fast. With a reduced cutting width, new teeth shapes and new carbide saw teeth, the new saw blades, which are perfectly designed for plunge-cut saws, ensure a high degree of cutting quality and extended service life – while maintaining a consistent cutting quality. The system is rounded off with clever system accessories such as guide rails, angle stops, a saw table and tried-and-tested details such as a splinter guard and a dust extraction system perfectly suited to the tool.

Interview with product manager Boris Seyfried at Festool

Product manager Boris Seyfried has seen the new plunge-cut saws through from the idea to market launch and answers a few questions about them below:

How long did it take to develop the new plunge-cut saws?

BS: We based this further development on our tried and tested TSC 55 and TS 55 R plunge-cut saws. It's taken us around two years to develop the new saw blade generation and the unique KickbackStop.

What is the development process for a new tool at Festool?

BS: To tailor product features precisely to specific requirements, we establish close working relationships with professional tradespeople, in which we continually look for solutions to their most important day-to-day needs. We then start with prototypes at the workshops and get feedback directly from the users. In addition, tradespeople from all relevant trades work for us and with us on product development – from the idea through to market launch. In parallel to the practical tests at our customers, our products are subjected to tough, week-long practical tests in our company's own testing laboratories and test stations. This is how we find and rectify even the smallest weaknesses long before series production. Only when robustness, reliability and service life are clearly proven are the products actually rolled out to the specialist retailers.

How does the new KickbackStop work?

BS: Our new KickbackStop technology is an active technology with which a kickback can be detected in good time. During sawing with the TSC 55 K, the KickbackStop's feeler wedge rests on the guide rail or on the material that is to be processed. If there is a kickback when sawing or plunge-cutting into the workpiece, the KickbackStop sensor wedge detects this immediately and initiates a rapid stop practically at the same time. This stops the plunge-cut saw from moving backwards unpredictably and therefore minimises the risk of injury. Important to know: The KickbackStop technology works without causing damage and is ready for immediate use again once it has been triggered, without needing to replace the saw blade or any other components.

PROFESSIONAL TIP Avoid kickback and saw safely

- Support tools with large boards to reduce the risk of kickback due to the saw blade getting stuck.

- Always place your other hand on the additional hand grip so that the tool can be properly controlled.

- Do not use blunt or damaged saw blades as this is an additional potential hazard for kickbacks.