Cordless angle grinder AGC 18-125 5,0 EBI-Plus

Functions

The robust solution for cutting and grinding.

The powerful AGC 18 cordless angle grinder is dust-resistant and long-lasting thanks to the enclosed brushless EC-TEC motor and protected electronics. The continuously adjustable speed of 4500 to 8500 rpm ensures that cutting and grinding is tailored to the material. The AGC 18 is logically designed for optimum ergonomics during cutting work. For especially smooth operation and fewer vibrations, the motor and housing can be disconnected.

- Robust and long-lasting: Enclosed motor and cast electronics are safely protected against dust

- Work appropriately for the material: Speed can be continuously adjusted between 4500 and 8500 rpm

- Ideal ergonomics for cutting work: Its design means that it fits well in the user's hand, runs smoothly and generates few vibrations

- Get results fast: Thanks to the powerful, brushless – and therefore maintenance-free – EC-TEC motor

- All-inclusive safety while working: Soft start-up, electronic overload protection, motor brake and restart protection ensure safe work

- Systems get it done – compatible with battery packs from the BP 18 series

- Safe investment: Fully covered by comprehensive Festool Service

- Packed in a Systainer³, the cordless angle grinder can also be seamlessly integrated into bott vehicle equipment for easy transportation from the workshop to the construction site. Systainer³ products are compatible with one another and can be connected to all previous Systainer generations, mobile dust extractors and many other system accessories, such as roll boards or the mobile workshop

Product details

Usage

Main applications

- Cutting the toughest materials (metal, stone and concrete materials)

- Easy grinding and roughing work (e.g. deburring metal)

Technical Data

-

Lithium-ion battery

Fitted with high-performance lithium ion battery pack.

-

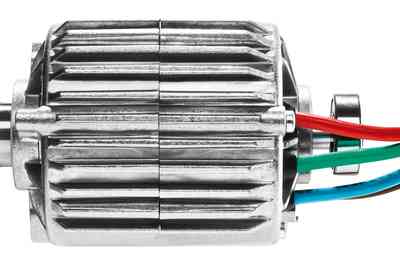

EC-TEC motor

The EC-TEC drive concept generates an extraordinary amount of power while consuming extremely low amounts of energy.

-

MMC digital electronics

Processor controlled “Multi Material Control” power electronics provide adjustable and constant speeds as well as temperature monitoring for work on all types of material.

-

Electronic overload protection

Protects the motor with blocking tool.

-

Quick-acting brake

For safe work when planing, sawing and routing.

-

Electronic monitoring of the winding temperature

Electronic monitoring of the coil temperature protects against damage to the motor.

Downloads

Accessories

You can view 8 of 16 possible accessory items here. You can view 4 of 16 possible accessory items here.