Joining machine DOMINO XL DF 700 EQ-Plus

Items included

-

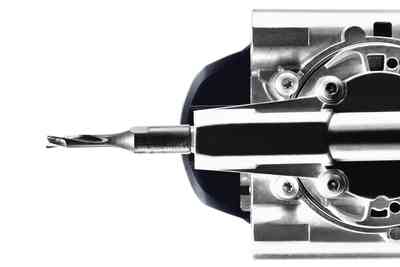

- DOMINO cutter D 12

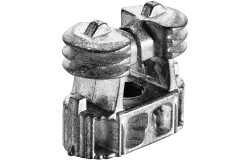

- Additional stop

- empty dowel box

-

- open ended spanner, WAF 12

- plug it-power cable (4 m)

- Systainer SYS3 M 437

Functions

Extra mobile. Extra stable.

Comes to the workpiece and not vice versa: DOMINO XL. Quick, simple, precise and extremely stable - with measurably shorter tooling times and up to 50% time-saving in comparison to stationary machines. The DOMINO XL is therefore ideally suited for furniture and door construction and solid wood joints.

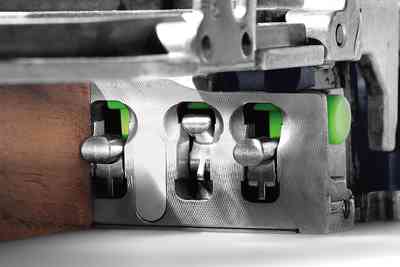

- Maximum stability of joints up to a DOMINO size of 14 x 140 mm

- Patented routing principle unique to hand-held machines for accurate work with no kickbacks

- Saves more time compared to a stationary machine

- Stops that are quick and easy to adjust, for accurate results

- System accessories compatible with both DOMINO jointers

Product details

Usage

Main applications

- Solid wood furniture in frame and tunnel design

- Frame construction of house doors and interior doors

- Manufacture of tables and chairs

- Creation of stable mitre joints

- Folded and profiled door frames in furniture construction

- Connection of wide cornices (e.g. plates)

- Frame and stand constructions in non-supported timber structure (exterior and interior area)

Technical Data

-

Antistatic function

Mobile dust extractors and tools with the antistatic function to prevent static charge from accumulating when working.

-

CLEANTEC

Integrated bayonet fitting as the connecting element between the extractor and the tool.

-

Electronic

Speed control for adjusting to all types of materials.

-

Plug it

Removable, replaceable mains cable with safety lock for quick conversion.

Downloads

Accessories

You can view 8 of 43 possible accessory items here. You can view 4 of 43 possible accessory items here.