Circular-/plunge cut saw blades

Your saw deserves the best saw blade – for all sawing applications. Our circular saw blades are optimised for your particular type of work and machine. You can always rely on completely smooth operation, and saw efficiently with high cutting performance and quality. High-quality, robust carbide teeth ensure your sawing operations remain enjoyable over the long term: Long service life with consistently good results and excellent sharpening properties, as they can be resharpened up to eight times.

Discover how our circular saw blades can help you.

Quick access to the right blade.

WOOD FINE CUT

WOOD UNIVERSAL

WOOD RIP CUT

LAMINATE/HPL

ALUMINIUM/PLASTICS

ABRASIVE MATERIALS

Tailored to your perfect cut: Cutting angle, number of teeth and tooth geometry

In addition to matching the material to be sawn, the cutting angle, tooth geometry and number of teeth also play a decisive role when sawing. As a general rule:

- The higher the number of teeth, the better the cutting result.

- Therefore, if you need a clean, precise and splinter-free cut for your application, you should choose a circular saw blade with many teeth, as these cut the material consistently.

- A blade with a lower number of teeth is sufficient for separating cuts, for example on invisible edges or in coarse materials such as OSB boards, where speed is more important than a splinter-free cutting edge.

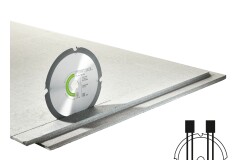

The cutting direction is also crucial for woodwork.

- Saw blades with more teeth are generally better suited to cuts across the grain.

- When cutting lengthways in the direction of the grain, you can often cut more efficiently with fewer teeth.

The smallest detail makes all the difference – the tooth geometry describes the specific shape and arrangement of the teeth on the blade. It has a significant impact on the way the saw blade cuts the material. We have summarised the most important tooth shapes for you:

Tooth shapes

Small details with a big effect.

Sharp for longer

Smooth and low-vibration.

Thinner, faster, further.

How can I tell when a saw blade is blunt?

Cutting results

Effort

Burns and discolouration

Unusually loud noises

Just right for your saw.