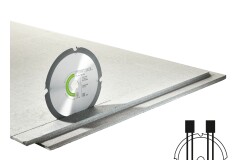

Saw blade ALUMINIUM/PLASTICS HW 168x1,8x20 F/FA 52

for TS 60 K, TSV 60 K, CSC SYS 50

Item number 205767

Functions

Quality cuts better.

Durability and precision under the toughest conditions. Adapted to the application and material. Made from high quality steel with saw teeth made from fine grain carbide. After all, you can only achieve a perfect cut when the saw blade is as good as the machine.

- The systematic solution for cuts in aluminium and plastic

- Saw teeth made of high-quality metal – for optimum saw progress and perfect cuts

- Cutting angle and tooth shape are adapted to the application and machine

- Flat tooth with variable chamfer for consistent quality and a long service life

- Ideally tailored to your saw – for exact, efficient working

- Colour coding makes it easier to select the correct saw blade

- for aluminium panels and profiles, perspex, hard and fibre-reinforced plastics, non-ferrous metals, aluminium composite panels

Usage

Main applications

- For machining aluminium composite panels

- Cutting non-ferrous metals such as copper and brass

- Cutting twin-wall sheeting

- Cutting plastic-based materials such as phenolic-resin-bonded fibres and fabrics, PVC and acrylic glass

Technical Data

Technical data

Diameter

168 mm

Cutting width

1.80 mm

Hole dia.

20 mm

No. of teeth

52.00

Chip angle

-5.00 °

Standard blade thickness

1.20 mm

Tooth shape

F/FA

Relief angle

20.00 °