Cordless freehand cutting system DSC-AGC 18-125 FH EB-Basic

Items included

-

- extraction hood

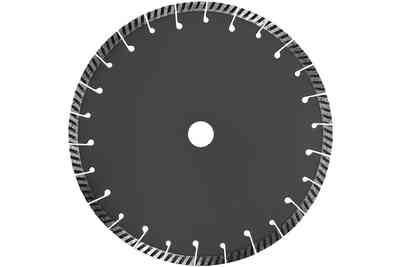

- ALL-D125 Premium diamond cutting disc

- plate TP-DSC-AG 125 FH

- Auxiliary handle VIBRASTOP

-

- clamping nut UF-DSC/DSG-AG M14

- flange BF-DSC-AGC M14

- KF-AG face wrench

- Systainer SYS3 M 187

Functions

For accurate separating cuts without dust.

For healthy work, the dust extraction attachment conveys over 95% of the dust directly to the mobile dust extractor – ideal for dust-free cutting of mineral materials indoors. The open design enables a clear view of the cutting line, making orientation along the scribe mark simple. The dust extraction attachment can also be opened easily to allow work close to edges. Additionally, the enclosed EC-TEC motor and the protected electronics guarantee dust resistance. The Bluetooth® battery pack automatically starts the paired mobile dust extractor for even more comfortable work.

- Work more healthily with the dust extraction attachment: Over 95% of dust produced is transported directly to the mobile dust extractor – ideal for dust-free cutting of mineral materials indoors

- Precise, unrestricted cutting: Clear view of the scribe mark thanks to the open design of the dust extraction attachment

- Cuts up to the edges: The dust extraction attachment can be opened easily at the front to allow work close to edges

- Long-lasting: Enclosed brushless EC-TEC motor and cast electronics are safely protected against dust

- Mobile: Packed in a Systainer³, the cordless freehand cutting system can also be seamlessly integrated into bott vehicle equipment for easy transportation from the workshop to the construction site Systainer³ products are compatible with one another and can be connected to all previous Systainer generations, mobile dust extractors and many other system accessories, such as roll boards or the mobile workshop

Product details

Usage

Main applications

- Cutting and trimming mineral panels such as tiles and natural stone

- Creating cut-outs on walls and concrete to repair damage

- Repair of cracks

Technical Data

-

Lithium-ion battery

Fitted with high-performance lithium ion battery pack.

-

EC-TEC motor

The EC-TEC drive concept generates an extraordinary amount of power while consuming extremely low amounts of energy.

-

MMC digital electronics

Processor controlled “Multi Material Control” power electronics provide adjustable and constant speeds as well as temperature monitoring for work on all types of material.

-

Electronic overload protection

Protects the motor with blocking tool.

-

Quick-acting brake

For safe work when planing, sawing and routing.

-

Electronic monitoring of the winding temperature

Electronic monitoring of the coil temperature protects against damage to the motor.

-

CLEANTEC

Integrated bayonet fitting as the connecting element between the extractor and the tool.

Downloads

Accessories

You can view 8 of 13 possible accessory items here. You can view 4 of 13 possible accessory items here.