Joining machine DOMINO DF 500 Q-Set

Functions

More precise joints.

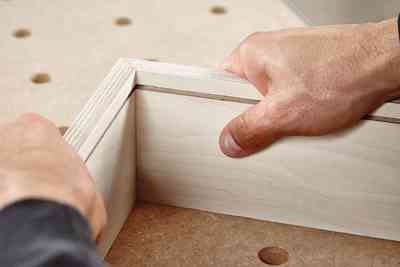

Oval shape, larger glued area, more stability. The DOMINO system unites the precision of a round dowel with the flexibility of a traditional flat dowel – the perfect solution for panel joints. The system consists of the DF 500 dowel jointer, DOMINOs in different sizes and a wide range of accessories for special applications. The result: extremely strong, invisible joints. And DOMINO can do much more: rack joints, frame joints, drawer joints, etc.

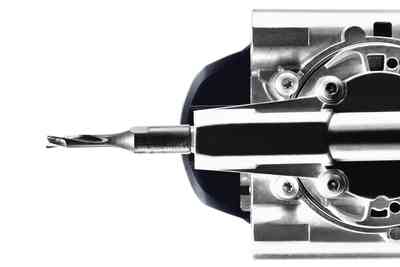

- Patented routing principle unique to hand-held machines for accurate work with no kickbacks

- Stops that are quick and easy to adjust, for accurate results

- Rotation-proof joint with DOMINO dowels providing maximum stability

- System accessories compatible with both DOMINO jointers

- Varied use with dowel sizes from 4 x 20 mm to 10 x 50 mm

Product details

Usage

Main applications

- Furniture manufacture

- Shopfitting/Interior fitting

- Window construction

- Exhibition stand construction

- For panel joins

- For frame and rack joints

Technical Data

-

Antistatic function

Mobile dust extractors and tools with the antistatic function to prevent static charge from accumulating when working.

-

CLEANTEC

Integrated bayonet fitting as the connecting element between the extractor and the tool.

-

Plug it

Removable, replaceable mains cable with safety lock for quick conversion.

Downloads

Accessories

You can view 8 of 50 possible accessory items here. You can view 4 of 50 possible accessory items here.