Healthy work – relax and breathe

Effective health protection with the right system

Three experts who know the score

"Every euro invested in health and safety in the workplace pays off double. In small companies in particular, injuries and illnesses can represent existential threats."

Alexander Hoste, occupational health and safety expert

Healthy, safe and simply a matter of course

Work healthy and stay healthy in the long term

Improved health. Less downtime.

Health and safety in the workplace are not only neglected in the painting trade, and the consequences are generally underestimated. The facts speak for themselves.

Why workers in the industry miss work for health reasons

33.5% musculoskeletal disorders

17.2% injuries and poisoning

14.5% respiratory illnesses (IKK classic Report 2018, Germany)

Worldwide, one worker dies every five minutes as a result of cancer caused by exposure to asbestos. (Institution of Occupational Safety and Health (IOSH), UK

Investing 100 euros in health and safety in the workplace brings beneficial returns of 220 euros in the long term. This was shown by a two-year long-term study in 16 countries. (Justus Liebig University Giessen and Institute for Work and Health of the German Social Accident Insurance)

50.8% of missed workdays in the industry can be attributed to long-term illnesses (over 42 days). (IKK classic Report 2018, Germany)

Protect yourself

Safety glasses...

Dust masks...

Work gloves...

Safety shoes...

Dust-free work with a system

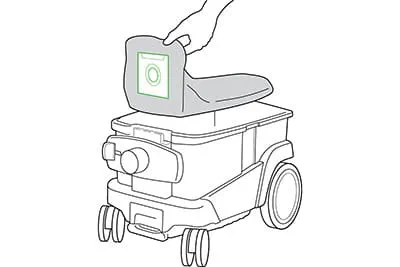

Closed system

Mobile dust extractor + SELFCLEAN filter bag (single-use, seal with the cardboard closure on the filter bag and then dispose of it).

›› Especially on building sites or when sanding with wood dust, it is important to observe the dust category of the mobile dust extractor.

›› For extracting normal amounts of dust, such as when using manual sanders.

›› High-quality non-woven filter bag, cleans dust deposits inside the filter bag automatically; optimum utilisation of filter bag capacity and consistently high suction power thanks to SELFCLEAN filter bag; secure connection to the antistatic suction hose with connector sleeve and rotating adapter.

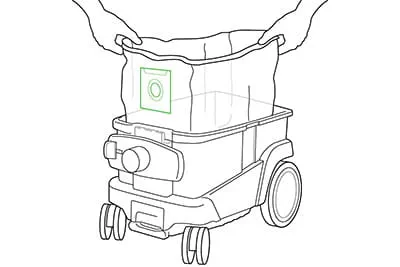

Open system

Mobile dust extractor with AUTOCLEAN filter cleaning + disposal bag made of plastic (single-use, seal with the supplied cable tie and then dispose of it).

›› When working with mineral dust, using a dust extractor with dust category M is necessary.

›› For extraction of large amounts of dust, especially when using long-reach sanders and renovation millers.

›› The AUTOCLEAN automatic filter cleaning function ensures constant, powerful suction (the filter is cleaned even more thoroughly thanks to the extreme vacuum); the plastic disposal bag allows for low-dust disposal.

Dust protection tips for professional painters

An overview of the most important aspects

Wear a dust mask and safety glasses

For total safety, it is a good idea to wear a dust mask when removing substrates that produce heavy dust or when working with materials that are especially harmful to health. Safety glasses protect your eyes from flying dust particles and chips.

Ensure connection is secure

Every weak point risks your health. That’s why it’s essential to ensure that the connection between your tool and the hose is secure and that the hose in turn is securely connected to the dust extractor (and has the correct diameter).

Use low-dust procedures

Avoid creating dust clouds even when mixing fillers, using the new MX extractor, for example.

Use consumables as intended

The condition of the abrasive has a significant effect on the dust extraction. during sanding. The system can only achieve optimal suction power with a good abrasive.

Choose a suitable dust extractor

It is important to choose a mobile dust extractor with a dust category that is appropriate for the material being worked on. The kinds of dust generated can be divided into three categories: L, M and H.

Vacuum dust

Clean your workspace regularly. Vacuuming is much more effective and targeted than sweeping or blowing away dust or chips.

Safe and healthy work is important

›› Customers are happy when you leave the building site clean and finish your work more quickly with minimal dust.

›› Employee health and safety is a priority – this signal strengthens employee loyalty in times when qualified staff are hard to find.

›› Sick employees cost the company a lot of money and they are less productive.

›› A company health and safety policy ensures that your business complies with applicable regulations.

›› The German Social Accident Insurance Institution for the construction sector (BG BAU) subsidises the procurement of necessary equipment.