A perfect surface in seven steps

Festool trainer Dino Frey shows how to achieve perfect surfaces in just a few steps.

Dino Frey is a Festool trainer and master painter by trade.

Step 1: Stirring the material

Step 2: Applying the material

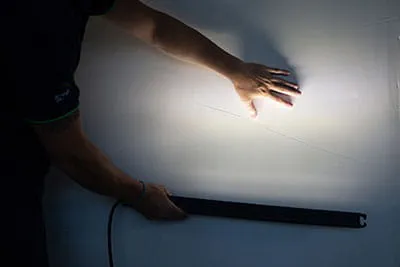

Step 3: Inspecting the surface

Step 4: Preparing the mobile dust extractor and long-reach sander

Step 5: Selecting the right abrasive

"Perfect surfaces don't just happen. Good preparation is an absolute must."

Dino Frey, Trainer and Application Specialist at Festool

Step 6: Internal or external extraction?

One last question before we start: Should the Planex be set to internal or external extraction? For ready-made fillers that produce large quantities of dust (ready-made dispersion-based fillers), the answer is clear: Due to the large volumes of dust that are generated, we recommend working with external extraction. Then you can evenly sand off the surface with the Planex.

Step 7: Final inspection