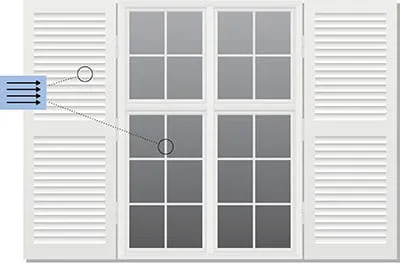

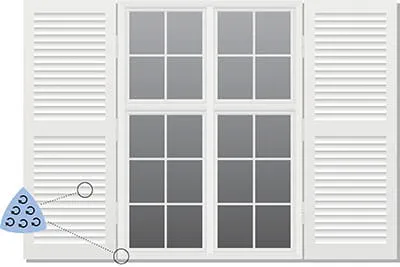

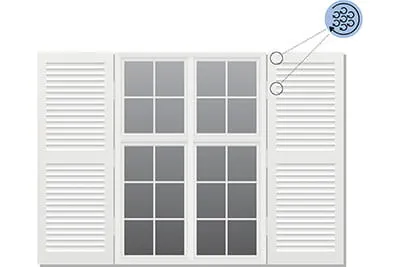

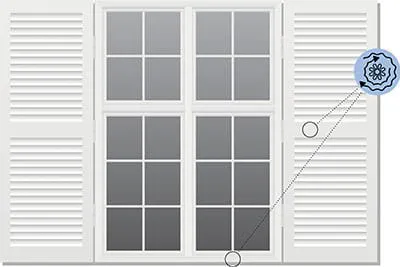

Sanding motion: Pure linear motion.

Application: Linear motion is ideal for sanding wood material along the grain.

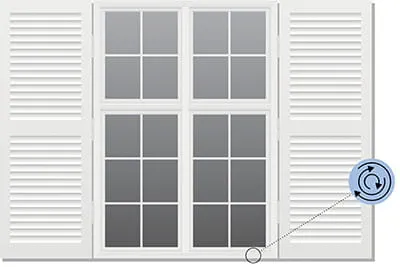

Note: Sanding with a linear motion along the grain does not damage wood fibres (important if the surface is to be oiled, waxed or coated with a thin layer of varnish afterwards, for example). The linear sanding motion does not go out to the sides; linear sanders are therefore ideal for sanding frame sections adjacent to panes of glass.

Example machine: DUPLEX LS 130 linear sander