Edge router OFK 700 EQ-Plus

Items included

-

- Ø 8 mm clamping collet

- 1.5° router table

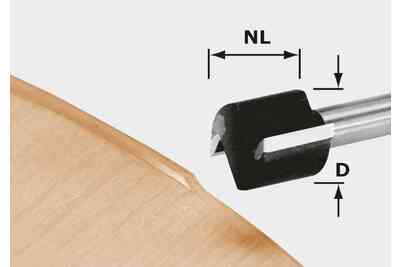

- edge trimming cutter D 19 x 16

-

- open ended spanner, WAF 19

- plug it-power cable (4 m)

- Systainer SYS3 M 187

Functions

Edging multi-talent.

Impressive on straight edges and curves: The OFK 700 edge router is the multi-talent among edge routers. It makes easy work of trimming edges and surface projections, irrespective of whether the workpiece is large or small and whether the edges are curved or straight. The large, easy to attach router table provides a stable surface area and secure guidance for the machine in any working position.

- Detachable router table with large support surface

- Base inclined by 1.5° for excellent working results

- Routing depth adjustment to 1/10 mm

- Contact spring for smooth routing pattern

- Spindle stop for quick and easy cutter changes

Product details

Usage

Main applications

- For protruding edges and surfaces in plastic and wood

- Rounding and chamfering edges

- Routing grooves for inserting PVC edging

- Trimming laminated board flush

- Routing edge veneer on concave and convex parts such as round tables, desktops etc.

Technical Data

-

CLEANTEC

Standard connection (27/36/50 mm) for dust extraction, protects the operator and the environment.

-

MMC Multi Material Control electronics

“Multi Material Control” power electronics with constant adjustable speed and temperature monitor for work on all types of material.

-

FastFix

Makes changing routing, sawing, planing, sanding, drilling and screwdriving tools easier.

-

Plug it

Removable, replaceable mains cable with safety lock for quick conversion.

-

Antistatic function

Mobile dust extractors and tools with the antistatic function to prevent static charge from accumulating when working.

Downloads

Accessories

You can view 8 of 39 possible accessory items here. You can view 4 of 39 possible accessory items here.