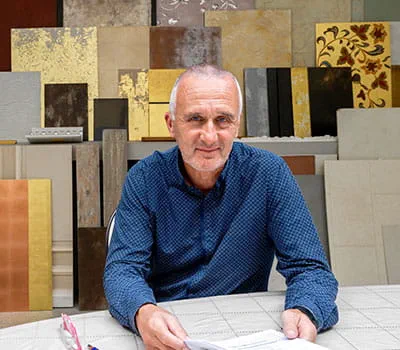

The owner, Didier Lebon, greets us warmly. He leads us through the workshop to the showroom, the heart of his company. Sample panels are lined up against the walls, the results of experiments and sampled surfaces for customer projects. All of the materials, techniques and surface qualities are prepared, tested and approved by the customer before the final creation is produced, says Lebon, who goes on to explain, ‘We get lots of unusual requests from architects and designers. They know we’re able to propose and execute solutions that meet their expectations, so they come to us directly.’

Haut de Gamme

Founded in 1962, the Didier painting company has been owned and managed by Didier Lebon since 2000. Today it has 40 employees. The company specialises in high-end paintwork and surface finishes, which it delivers at the highest level – through expert craftsmanship in connection with modern techniques and tools.

The sun shines over the Côte d’Azur – but we would expect nothing less. Our sat nav guides us into the city centre of Nice, where the Didier painting company is located. Here, we’re told, is where truly extraordinary things are created – made at the highest level of craftsmanship out of carefully selected, exclusive materials.

The painting company has worked hard to cultivate its excellent reputation. When Roger Didier took over the business from his father in 1972, he successfully built up the Didier company over almost 30 years before selling it to Didier Lebon in 2000 and retiring. Since the surname of the previous owner was the same as his first name, Lebon decided not to change the company name. With great perseverance and dedication, he continued to develop the business. In the meantime, he has come to employ forty members of staff. They have all internalised the high standards of their boss – not because they were forced upon them, but because they really value the high-end level of work, which constantly pushes them to take on new challenges.

From simply looking at the list of prestigious projects the Didier company has completed, it is clear why the teams are rather proud of their involvement: From projects like gilding the Rotunde brasserie in the grand Hotel Negresco, which was built in 1912 on the Promenade des Anglais in Nice, to renovating the Montgolfier villa in Théoule-sur-Mer, a villa owned by the Montgolfier brothers, who invented the hot air balloon at the end of the 18th century. The Didier company has even worked in the Louvre in Paris. Didier Lebon could spend hours regaling us with stories about the countless projects he has put so much knowledge and passion into. But instead, he wants to take us to one of his construction sites, where he and his teams are currently working.

We set off by car towards Villefranche-sur-Mer to a neighbouring locale around 20 minutes from Nice. The drive is a pleasant journey, taking in views of the Mediterranean Sea from the passenger seat. When we arrive at the construction site, the sea is literally at our feet. It’s hard to imagine how anyone can work here without being distracted by the outstanding view. The Villa La Cascade literally cascades down a south-facing slope like a stairway. The construction project involves renovating the existing building and adding an extension. All of the paintwork is being done to the highest standard, including even how the substrates are prepared, and extending to refining them with specific paints, ornamental materials and high-end wallpaper.

The Didier team is skilfully crafting an exclusive reed decoration on the wall. In the extension, they are giving three columns a marble aesthetic that requires a perfectly prepared substrate, which is then painted and polished. ‘Having the perfect tools for our needs is the most important thing for us,’ emphasises Didier Lebon. He even had a custom smoothing trowel made for his company. Especially high-quality surfaces are created using Festool sanders and abrasives with a grit of up to 4000.

‘Having the perfect tools for our needs is the most important thing for us.’

Didier Lebon

The employees are testing the new PLANEX LHS 2 225 long-reach sander for the first time. They are impressed by the light ring, which allows them to assess the surface quality even as they sand, eliminating the need to rework the area afterwards by hand. ‘The vacuum function means that my employees can sand and work dust-free without tiring, which really makes the job easier. The health and well-being of my employees is my top priority,’ emphasises Didier Lebon.

The Didier teams are currently working on ten construction sites at the same time. That requires flexible planning, perfect preparation in the workshop and concentration during execution on-site.

Back at the company premises in the late afternoon, Didier Lebon coordinates the work for the coming days and weeks. And late into the evening he does what he loves to do – experiment with choice materials and innovative techniques on totally new décors. His knowledge and skills come from years of experience. The unstoppable curiosity and passion for trying out new things are what drives him.

How does he manage to maintain such a high standard of craftsmanship? ‘It’s not easy,’ he admits. After all, customers are wanting projects finished more and more quickly, making coordination with all of the other trades even more difficult. ‘On the other hand, we benefit from the fact that the tools and accessories we use are constantly improving our working conditions,’ the boss says. ‘Festool is the best example of this – and we work closely with product developers to incorporate ideas for improving the products from our high-level work. When it comes to product quality, reliability and service, the three-year warranty is at least as important to me as the performance capability of the machines.’

Ultimately, Didier Lebon can only live up to his good reputation and the promises and expectations it brings if he delivers the highest level of quality at the end of every single project. And he and his company manage to do that in an impressive way.