Full speed ahead

Construction of solid-wood houses using durable cordless tools

Solid-wood houses are becoming ever more popular in Germany. This is not just due to their appealing architecture and the growing interest in wood as a natural building material – the houses also take less time to build. This is particularly the case when using durable cordless tools, such as the DRC 18/4 cordless drill or the HKC 55 cordless circular saw.

Batteries at full load

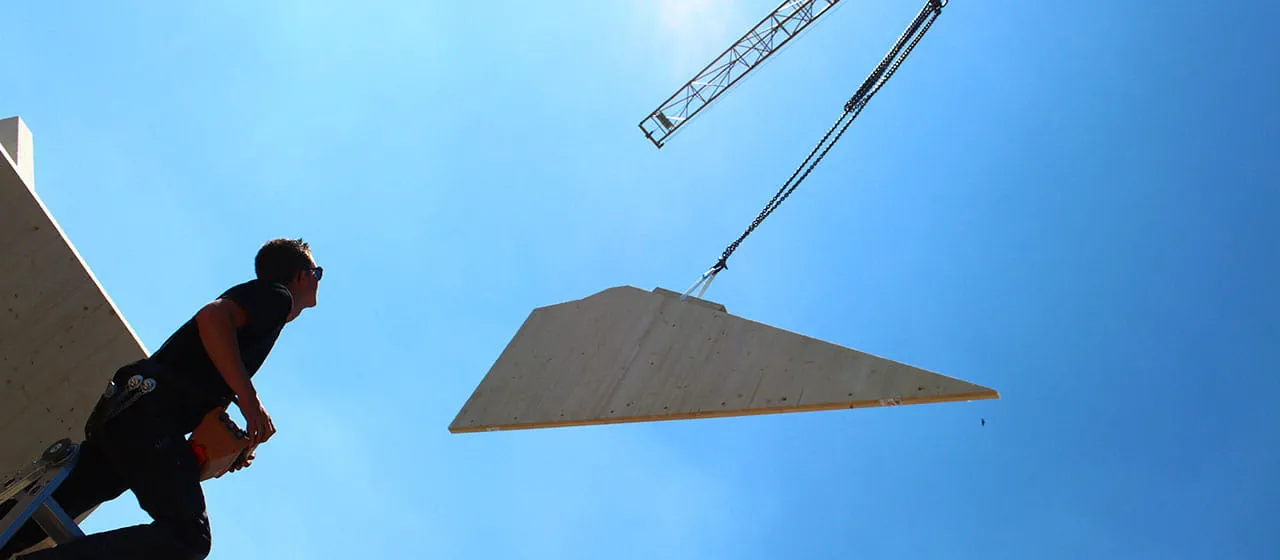

With a slight whir, the 8 mm screw disappears into the wooden wall element that the crane lifted into position just a few minutes ago. It isn't the first screw for the DRC 18/4 cordless drill today – four carpenters have been busy screwing the solid-wood elements together since the early hours of the morning. For the 5.2 Ah batteries, this means working at full speed under the blazing summer sun. Both carpenter and machine – and especially the battery – are working up quite a sweat. But neither has time to take a break: The next wall and ceiling elements are already on the lorry parked beside the construction site and waiting to be lifted into position by the crane.

There's good, there's better – and then there's wood

While the next element is being prepared and transported to its intended location, we have a few minutes to examine what makes solid-wood houses special: The walls and ceiling elements of the solid-wood house are made from multiple-layer cross-laminated spruce. The fine grain and light colour – and of course the wood itself – later make for a pleasant and comfortable living environment. The added insulating materials made from mineral materials or soft wood fibre ensure good thermal insulation during the winter months.

Cordless sawing and screwdriving

In addition to the time factor, it is mainly the independence of the cordless tools that facilitates work for carpenters out here. "Anything that doesn't require a socket and has a powerful battery is a welcome sight," one of the carpenters tells us. He laughs, but he is serious: "We need to move fast on the construction site, including when spontaneous adjustments are required. Creating a recess or sawing off a roofing board? If you have to lay cables every time, that can quickly turn into a complicated and time-consuming operation." He grabs the HKC 55 cordless circular saw with the FSK 250 cross cutting guide rail, climbs up one floor on the scaffolding and swiftly removes a protruding wooden slat. Safety is another advantage of cordless tools: Cables on a construction site can quickly become tripping hazards – potentially disastrously so in a job where a scaffolding is often the only thing preventing a fall.

"The tricky thing is finding the right balance between torque and speed."

Carpenters

Man and machine

Two hours, four walls and numerous screws later, the time has finally come: The ceilings are lifted into place by the crane. With the DRC 18/4, the four carpenters drill the large screws into the rough-drilled holes in next to no time. The battery only needs to be charged once. But at no point do things get hectic with this well-coordinated team. "The tricky thing is finding the right balance between torque and speed. Drilling into fir wood at full speed isn't a good idea, because screws that have been turned in too deep could lead to unsightly splinters or even cracks. Our DRCs award us perfect control in this regard," the foreman explains. The solid-wood roof trusses are next. The crane driver gently positions them before they are carefully fitted by two colleagues. One of the beams seems to be slightly the wrong size – it doesn't quite want to engage in the bracket. After making some adjustments with the HKC, the issue is quickly resolved. The stubborn beam now fits perfectly. Timber construction can be as easy as that – if man and machine work together seamlessly.

The cordless drill DRC 18/4 from festool in side view.

A carpenter screws some wall elements with the cordless dril DRC 18/4 from Festool.

A carpenter with the cordless drill DRC 18/4 from Festool on top of a solid-wood house.

A carpenter with the cordless drill DRC 18/4 from Festool on top of a solid-wood house.

The cordless drill DRC 18/4 from Festool in action.

The cordless drill DRC 18/4 from Festool in action.

The cordless drill DRC 18/4 from Festool in action.

The HKC 55 cordless portable circular saw in side view.

The HKC 55 cordless portable circular saw from Festool in action.

A carpenter put the roof beam in the right position.

A wall element of the solid-wood house is positioning.

A piece of wood of the solid-wood house.

1 / 1