One hundred percent quality

Delivery „just in time“

„Our staff on the assembly line have a very important role as inspectors and are therefore qualified accordingly.“

Ulrich Brunner - executive producer at Festool

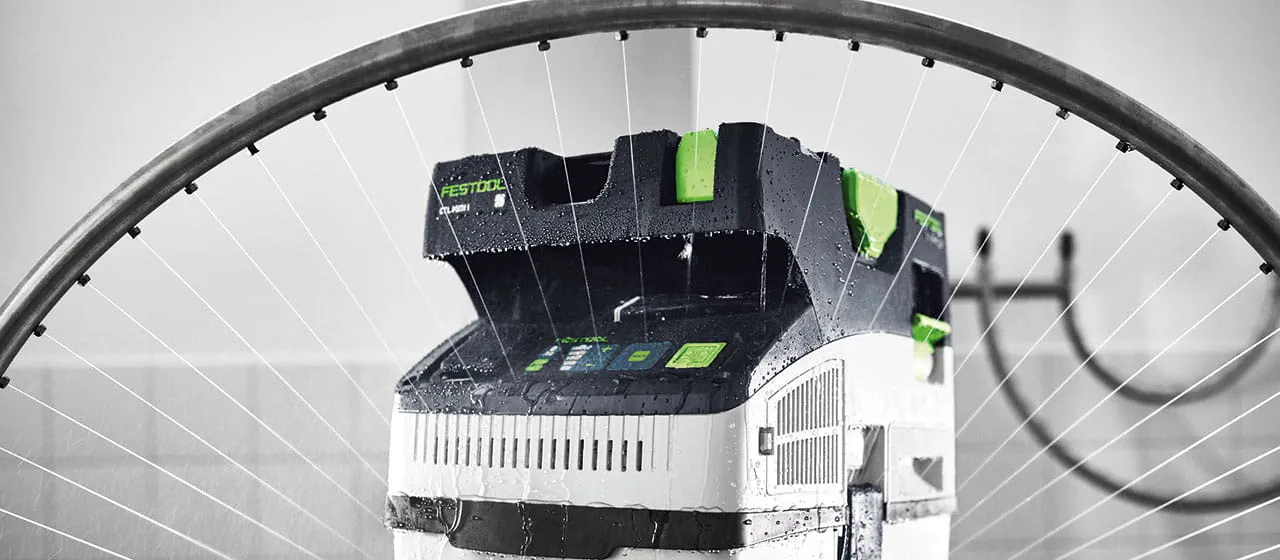

Practical boundary experiences in testing

Testing with wood and cement dust

Quality assurance on the assembly line

In the test chamber

At the end of the state-of-the-art assembly line is a test chamber, which has been developed completely from scratch. And it’s all because of the mobile dust extractors that are produced on the new production line. The new touch control panel, which has been introduced for the first time in the CT MINI and MIDI compact dust extractors, requires completely new test methods. What’s more, it is the first test system with Bluetooth® technology*. Finally, cordless functions also have to be given a final inspection before the mobile dust extractors are shipped. The amount Festool has invested in quality assurance is certainly impressive. That applies to the tools and mobile dust extractors in equal measure. As far as Ralf Bärreiter is concerned, it’s a core part of the business: ’If it means we can guarantee the quality of our products with absolute certainty, nothing is too much. We do whatever it takes. And even a little more, too.’