A good drivetrain is everything

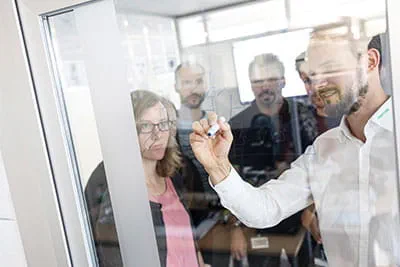

A motor is the core component of any power tool. But a good motor isn't everything: It is dependent on perfect interaction between the battery and the motor, which is especially the case for cordless power tools. Lead developers Fabian Grass and Martin Graf tell us in an interview how important this teamwork between the battery and electric motor is for day-to-day work on the construction site.

How important is a good motor for a power tool?

Fabian Grass: Festool always strives for the highest degree of perfection when developing and manufacturing its tools. We've carried over this aim to our drivetrains. Motors are the core component of a power tool, which means they have a direct influence on work results and progress. As a part of the electric drivetrain, the motor also has a deciding influence over the machine's performance.

What is the difference between modern motors and old motors?

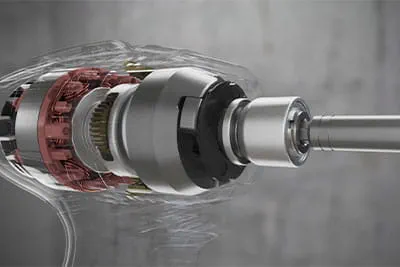

FG: Alongside the constantly increasing power requirements, characteristics such as speed, protective mechanisms, efficiency, wear-free operation, weight and design size are becoming more and more important. On our power tools, "EC" stands for "electronically commutated" – which is another name for brushless technology.

Brushless motors are now the industry standard. What makes our Festool motor technology stand out from the crowd?

FG: We have many years of experience with brushless motors behind us. We have used them to provide the appropriate motor for every application in the cordless and mains-connected range with the new modular motor and its diversity. Our users will experience and see in practice in individual sectors that this has been a sustained success for us.

Does Festool still install brush motors, or are only brushless motors used?

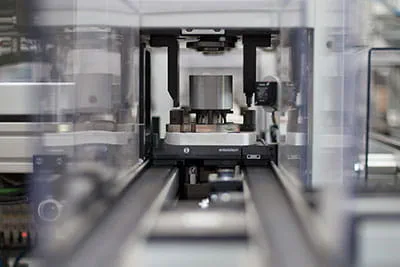

FG: In the future, we will also install brush motors. They will be used in machines where the advantages of brushless motors play a less important role. Furthermore, we also produce these motors at our Neidlingen site. Here too, we find that we are constantly in the process of optimising and developing further so as to meet the future requirements for applications.

What's the difference between motors with carbon brushes and brushless motors?

FG: Two essential differences are maintenance and power density. Brushless motors do not have carbon brushes that wear out over time, which enables us to produce low-maintenance power tools. This also results in a significant decrease in the number of components, which in turn has a positive effect on the installation space, weight and therefore power density. So, with brushless motors, we build smaller tools which require less maintenance, whilst also being more powerful.

Where are our motors manufactured? And, do all the components originate from us?

FG: Our motors are manufactured at our in-house motor factory in the Festool plant in Neidlingen, Germany. We rely on our long-term partnerships with international suppliers for individual components.

What effect do these modern motors have on the battery technology?

Martin Graf: The battery is indeed the energy source for the electric motor, which delivers a finite amount of energy, in contrast to a mains-connected device. This is why motors and drivetrains for cordless products in particular must demonstrate a high level of efficiency. A high level of efficiency means that both the motor and the drivetrain use the battery's energy efficiently, which makes it possible for the tool to have a long runtime and high performance. Therefore, our brushless EC-TEC motors have a significantly higher level of efficiency than motors with carbon brushes and are very well suited to cordless tools in particular.

"The best motor is no use without a suitable battery."

Martin Graf, Head of the Module Development department at Festool

So the motor and battery are a team and not components to be considered separately?

MG: Yes, it's an entire system that only works with all the parts together. The best motor is no use without a suitable battery.

Are batteries developed specially for motors?

MG: Yes and no – we develop drivetrain systems comprising the electronics, software, battery and motor. These systems are not always the same; instead, they are designed and optimised for the relevant application of the respective power tool. We develop the tool not only in terms of its ergonomic aspects, but also with regard to the motor, drivetrain and energy supply in a tailored way for the user.

What is noticeable about a good motor in everyday usage?

FG: A motor is good if the user perceives it in a positive way. This means that it generates a low level of noise, minimal vibration and low heat, yet at the same time displays high performance – all of that even after many years and countless hours of work in difficult conditions. That is our requirement for a good motor.

"A motor is good if the user perceives it in a positive way."

Fabian Grass, Team leader for Drivetrain Development at Festool

Are there different motors for different applications? Sanding is sometimes very arduous, while sawing requires a great deal of strength …

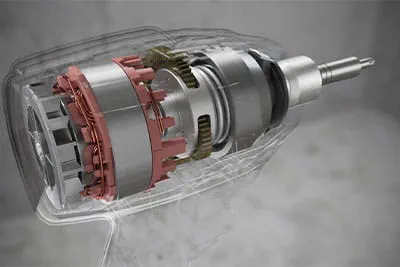

FG: Yes, exactly. Initially, we determine the power requirements in the form of a pyramid from "continuous" to "very short and intensive". Speed, which has a direct influence on the cooling of the motors, is also important. In accordance with our quality promise, we then choose between 1600 possible versions of a suitable motor with varying length and diameter, depending on the application.

How long have we been developing brushless motors at Festool?

FG: It's difficult to narrow down the date. Development began in around 2004 with the first EC-TEC motor generation. This was first used in a cordless drill. This EC motor has been constantly developed and used in various forms in cordless and mains-connected power tools. This motor is still used in our machines today, in parallel with the new EC 2.0 generation.

What is more important: Having the appropriate motor in the tool or the most powerful possible, regardless of application?

FG: The appropriate motor in the tool, of course.