PH: It's expected that lithium-ion cell technology will continue to lead to improvements in battery pack power and runtime. This will allow new cordless products to be created. In particular, e-mobility will be a driving force behind improved runtimes. This means that completely new product groups will be mobile, having been barely conceivable in cordless forms just a few years ago due to power and runtime reasons. At the same time, battery packs for smaller cordless assembly tools, like cordless drills, will become much more compact than they were a few years ago, while providing comparable power and runtime. Overall, we can say that there'll be particular growth in the product groups from the "non-drill" range – in other words, all the cordless tools which don't come under drilling or screwdriving.

Cordless and tailor-made

Tech Talk: Intelligent battery solutions from Festool

In this Tech Talk, we speak to Product Manager Patrick Hitzer (pictured on the left) and developer Patrick Schön (pictured on the right) about what makes a perfect battery and Festool's goals for developing future batteries.

What do our customers require from a battery?

Patrick Hitzer: It's hard to generalise because there's no typical customer, each trade – and, it goes without saying, each tradesperson – has specific needs for their cordless power tools. What's particularly important is that the battery and the power tool form a coordinated system and function together correctly. As with mains-powered machines, cordless machines must have the highest levels of power, durability and endurance. They should also provide the necessary power and runtime required and expected by our customers for them to complete their tasks. If, on top of that, the entire system is durable and does its job for many years, then we've achieved our goal.

Where's the development of battery technology headed? And how will the market develop?

What's the difficulty when developing new batteries?

PH: More powerful lithium-ion cell technology enables new cordless product groups to be created. These, in turn, place new demands on the entire system and on the battery pack itself. Their higher peak and/or continuous power must also be processed and cooled in the battery pack, at the interface and in the machine. What's more, the large battery packs should be ready for use again as soon as possible to enable continuous work without interruption. Once again, this places high demands on the charging technology. You also always have to think about compatibility with "old" cordless tools which are already on the market so that our customers have a functioning system which can be combined with any tool.

What's our objective? More and more power? Great and greater endurance?

PH: Our objective is to create a tailor-made battery solution which is bespoke to our machines and the requirements of our professional users. For some machines, this definitely means having a larger, more powerful battery pack. But other machines need a smaller, more compact and lighter battery pack which still provides sufficient power and runtime. We'll further expand our 18 volt system and focus on this aspect in the coming years. For products with very high power requirements, we'll implement "dual battery concepts" which meet these requirements while still being compatible with the 18 V system.

What role does the Internet of Things (IoT) play in developing new batteries?

PH: We believe that IoT is very important. Our focus is on digitalising and personalising tools to give customers real added value. Our Bluetooth® battery packs form the technical basis for our IoT functionality. Essentially, these act as a gateway in the communication between our machines, such as between the tool and the mobile dust extractor for the remote switch-on, or between the tool and our Festool Work App.

"Our customers should be able to achieve the same results with a cordless tool as they do with a mains-powered one."

Patrick Hitzer, Product Manager for Battery Technology

What requirements do we have when developing new batteries?

PH: We have many requirements when it comes to developing new battery packs. The most important ones are safety, quality, durability and – needless to say – power and runtime. Added to that, they should all be forwards- and backwards-compatible in our 18 V system. Finally, the battery packs need to fit our 18 V product range – "tailor-made" to make the perfect system for the relevant application.

What impact does the battery have on a tool?

PH: It has a big impact. A machine's battery pack forms the basis of its performance. But, when inserted, it's part of the tool, and therefore plays a key role in the machine having a comfortable weight and ergonomic handling. The battery is also important for enabling IoT functions, which are very helpful in everyday use. For example, if our Bluetooth® battery is connected to a Bluetooth®-compatible mobile dust extractor, it can switch the extractor on and off in auto-start. The battery acts as the IoT intermediary between the tool and your smartphone. Many more practical functions will be added both now and in the future via our Work App.

Do we always develop batteries to fit the tools or are batteries developed independently of tools?

PH: Both approaches are possible and they've both been used in the past. Generally speaking, battery pack systems can be developed independently of the tool but they're based on tools on the market or under development. In fact, we've also developed battery packs specifically to fit new cordless tools, like the Ergo battery packs for our RTSC 400, DTSC 400 and ETSC 125 cordless compact sanders. This was simply because a design based on a battery pack system didn't meet the target group of painters' needs with respect to handling and ergonomics.

How do we ensure the longest possible battery service life for our users?

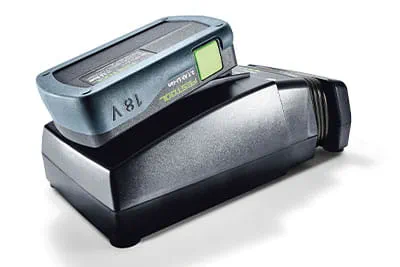

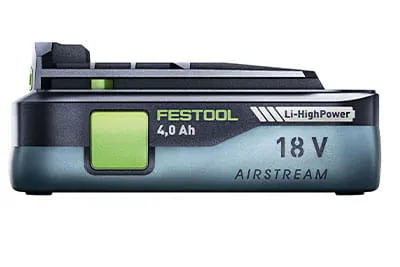

Patrick Schön: We only use high-quality, high-current cells from renowned cell manufacturers. Also, we only operate batteries within their approved specification and this applies to both the charging and discharge processes. We've also got various protective mechanisms which extend the expected service life of battery packs and their batteries. When it comes to battery deterioration, temperature is key. With our AIRSTREAM technology, we've therefore made it possible to cool the battery down prior to the charging process and to fully charge the cell with the maximum permitted charging current. The continuous increase in power density brought about by cell development means that service life and temperature management will continue to play a important role in our next generation of battery packs.

How can I extend a battery's service life as a user?

PS: This is mostly done by the machine in conjunction with our battery packs. But we're also always trying to further develop in this area and make our battery system smarter to give our customers greater and greater functionality and an even better performance, while also maintaining consistently high quality. Customers can extend a battery's service life by handling it correctly. For instance, a battery's service life will be affected by the storage temperature. You should therefore ensure that the battery pack isn't stored at high temperatures for long periods of time. Customers can also affect a battery's service life by how often they operate the battery pack until it reaches temperature shut-off. In this case, it may make sense to use a second battery before the first battery triggers the temperature shut-off.

What improvements in endurance can be expected from the battery of the future? What does the battery of the future bring to the table?

PS: A major driving force in cell development will certainly be e-mobility, which will pave the way going forward. The main focus in this area is battery capacity, which is synonymous with range. However, the factors of safety and costs are also very important. Some of our applications have similar capacity requirements, such as when using our extractors and sanders. We'd like these tools to provide moderate power for as long a time as possible. However, there are applications where maximum power is more important than the battery capacity. For example our saws are used in such high-current applications. Since we offer system batteries for our entire range of machines, high-current capability is just as important as capacity. To sum up, we can expect further improvements in capacity and high-current capability in tools of a comparable size in the next few years.

How can we take the issue of sustainability into account and incorporate it into the development of future batteries? What are we already doing in this area?

PS: There's great leverage for sustainability in the extraction of raw materials for batteries. At Festool, we've got the opportunity to ensure that cells are used more sustainably. For example, there's a lot of ideas in the area of second life batteries. While certain cells may no longer meet our requirements for applications, they still have enough capacity to be used in other energy stores. However, this would require a battery pack that is easy to remove. These considerations and much more besides are being taken into account in the development our next generations of battery packs.

What is more important: Having a good power tool or a good battery?

PS: There isn't a clear answer to this question since it's ultimately about having a perfectly coordinated system where the battery supplies the power tool with power for the required duration. So there's no point in a having a machine with reserves if its battery is too weak to use them, and vice versa. But, when developing power tools, you must ensure that energy provision is continuously developed and this makes new applications and approaches in machine development possible.